When you pick up a prescription, you rarely think about who made it or how much it cost to produce. But behind every pill, capsule, or injection is a complex system of labor, regulation, and economics - and the difference between a generic and a brand-name drug isn’t just in the label. It’s in the people, the processes, and the price tags.

Why Generic Drugs Are Cheaper - It’s Not Just the Ingredients

You’ve probably seen the price difference: a 30-day supply of brand-name blood pressure medicine might cost $120, while the generic version sits at $12. That’s not because the generic has cheaper chemicals. The active ingredient is identical. The difference? Labor. And how it’s used.

Brand-name drugs start with a massive investment. Developing a new drug takes about 10 to 15 years and costs around $2.6 billion on average. That money goes to scientists, clinical trials, regulatory filings, and years of failed attempts. The labor here isn’t just about making pills - it’s about discovery, testing, and proving safety. That’s why brand manufacturers spend 30% to 40% of their production costs on labor during the early stages.

Generic manufacturers don’t have that burden. They don’t need to re-prove the drug works. They don’t need to run new clinical trials. Their job is simpler: replicate the formula, meet the same quality standards, and produce it at scale. That simplicity cuts labor costs dramatically. For generics, labor makes up only 15% to 25% of total manufacturing costs. That’s less than half of what brand manufacturers pay.

The Hidden Labor Costs in Quality Control

Don’t assume lower labor costs mean lower quality. In fact, the opposite is true. Generic drug makers spend more than 20% of their total production cost on quality control - and most of that is labor.

Every batch of generic medicine must be tested for purity, potency, and consistency. Raw materials are checked. In-process samples are analyzed. Final products are inspected. Every step is documented. This isn’t optional. It’s required by the FDA. A medium-sized generic manufacturer spends about $184,000 a year just on compliance systems. Add in $1.9 million for program participation and $320,000 per new drug application, and you’re looking at serious labor investment.

That’s why quality control isn’t a cost center - it’s a survival tool. One mistake in testing or documentation can lead to a recall, a fine, or worse - a patient getting a bad batch. So even though generic companies have fewer R&D staff, they need more inspectors, lab technicians, and compliance officers. The labor is different, not less.

Scale Changes Everything

Imagine making one bottle of medicine. Now imagine making one million. That’s the scale difference between brand and generic production.

Generic manufacturers produce drugs in massive volumes. Nine out of every 10 prescriptions filled in the U.S. are for generics. That means factories run 24/7, often with automated lines. Labor efficiency improves with volume. Every time production doubles, unit costs drop by 27% for generics - compared to just 17% for brand-name biologics.

Why? Because fixed labor costs - like supervisors, quality managers, and maintenance crews - get spread thinner across more units. One lab technician can test 100 batches a week when production is high. When production is low, that same technician might only test 10. The cost per batch plummets with scale. That’s why generics can be so cheap: they’re made like cereal, not custom jewelry.

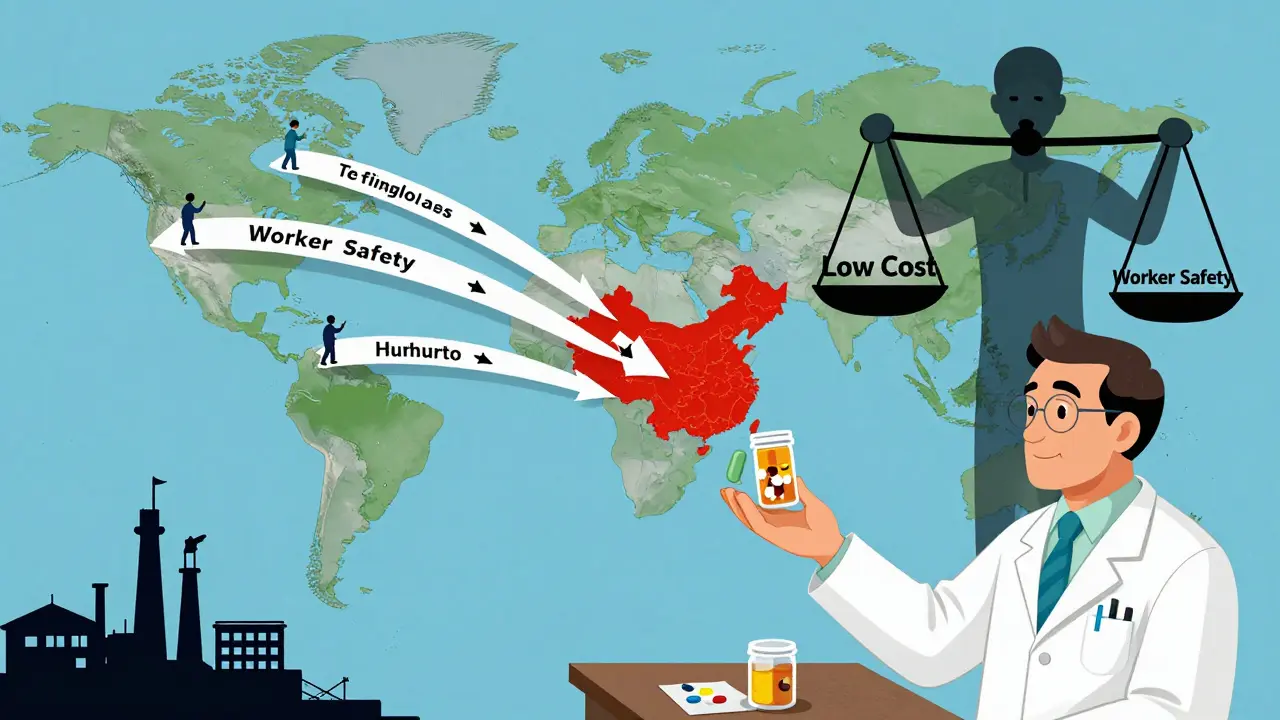

Where the Work Happens - and Why It Matters

Here’s the uncomfortable truth: a lot of the labor behind your generic drugs isn’t happening in the U.S.

Active pharmaceutical ingredients (APIs) - the core chemical components - are often made in India or China. Labor there is about 42% cheaper than in U.S. facilities. That’s not because workers are more skilled. It’s because wages are lower, regulations are looser, and environmental standards aren’t enforced like they are here.

That cost advantage flows into your pharmacy. It’s part of why only $36 of every $100 spent on generics goes to actual production. The rest? Profit, distribution, and overhead. But here’s the catch: those savings come with trade-offs. The U.S. Department of Health and Human Services warns that these low costs aren’t due to efficiency - they’re due to systemic imbalances. When you buy a cheap generic, you’re benefiting from a global labor system that doesn’t always reflect fair wages or safe working conditions.

Outsourcing Labor: The Rise of Contract Manufacturers

More and more generic companies are outsourcing production entirely. Instead of owning factories, they hire contract manufacturing organizations (CMOs). In biosimilar production, 42% of costs go to CMOs - compared to just 28% for small-molecule generics.

This shift turns fixed labor costs into variable ones. A company doesn’t pay salaries when production dips. They don’t hire full-time staff. They pay per batch. That gives them flexibility - but it also means less job security for workers. It’s a cost-saving tactic that helps keep prices low, but it changes the nature of the workforce.

For brand-name companies, outsourcing is rare. They need tight control over proprietary formulas and quality. For generics, it’s standard. The goal isn’t to build a legacy - it’s to produce as much as possible, as cheaply as possible, and move on to the next drug.

Competition Drives Labor Optimization - and Risk

The more generic competitors enter the market, the lower prices drop. That’s good for consumers. But it puts pressure on manufacturers.

The FDA has flagged this as a growing concern. When prices are squeezed, companies may cut corners. That means reducing staff, hiring less experienced workers, or slowing down testing to speed up production. One report found that supply shortages are increasing - not because of raw material shortages, but because companies are trimming labor to survive.

It’s a dangerous cycle. Lower prices → lower profits → lower labor investment → higher risk of errors → potential shortages. The system works when there’s healthy competition. But when too many companies chase the same tiny profit margin, someone has to pay - and that’s often the workers, and sometimes, the patients.

What This Means for You

When you choose a generic drug, you’re not just saving money. You’re participating in a global economic system built on scale, outsourcing, and intense competition. The labor behind your medication is real - it’s just spread across continents, hidden in contract jobs, and optimized to the extreme.

There’s no villain here. No evil corporation. Just economics. Brand-name drugs pay for innovation. Generics pay for efficiency. Both are necessary. But understanding the labor behind them helps you see why prices are what they are - and why sometimes, the cheapest option isn’t always the most sustainable.

If you’re on a fixed income, generics are a lifeline. But if you’re concerned about supply chains or drug safety, know that the pressure to cut costs doesn’t disappear - it just moves from the pharmacy counter to the factory floor.

Molly McLane

4 January / 2026Really appreciate this breakdown. I never thought about how much labor goes into quality control for generics - it’s not just about copying a formula, it’s about making sure every single batch is safe. That’s insane dedication from workers who don’t get any of the credit.

And yeah, the fact that most APIs come from countries with lower wages doesn’t make it wrong, but it does make me wonder how many people are working 12-hour shifts just to keep our prescriptions affordable.

Maybe we need a ‘fair labor’ label on meds like we do on coffee.